Induction Generators

Inductive Heating Systems for industrial processes

Induction heating is increasingly being used to heat flat or roller-shaped tools. Emission-free induction heaters not only provide heat as quickly as they can be turned off. The inductive heat distributes evenly up to 250°C and can be dynamically regulated. The technology is based on the eddy current principle. High-frequency alternating current generates an alternating magnetic field which is introduced into the metal in a defined manner. The resulting eddy current losses generate a thermal power that can be precisely dosed by changing the current flow.

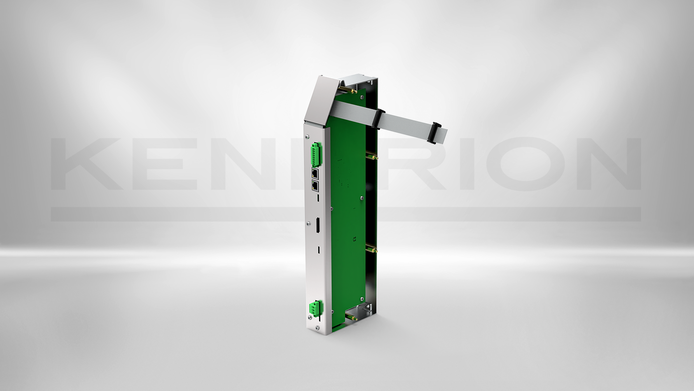

Kendrion induction generators are designed as a modular system. The generators consist of a controller and up to seven stackable induction generators. The controller can be integrated into the machine's control system via fieldbus interfaces such as PROFINET®, CANopen® or EtherCAT®. The individual induction generators can be controlled and status messages retrieved via the central controller. Depending on the configuration, the controller can also realize the control of the heating channels with integrated PID controllers. The devices are designed for control cabinet installation.

For special applications, Kendrion also develops customer-specific industrial heaters with integrated functions.

|

Title

ascending

descending

|

Type

ascending

descending

|

Device type

ascending

descending

|

Functions

ascending

descending

|

Field bus interfaces

ascending

descending

|

Product status

ascending

descending

|

Interfaces

ascending

descending

|

Modul bus

ascending

descending

|

Status indication

ascending

descending

|

Integrated I/Os

ascending

descending

|

Housing material

ascending

descending

|

IP-Protection Class

ascending

descending

|

Mounting

ascending

descending

|

Dimensions (W x H x D)

ascending

descending

|

Supply voltage

ascending

descending

|

Operating temperature

ascending

descending

|

Certifications

ascending

descending

|

Load type

ascending

descending

|

Number of channels

ascending

descending

|

Operating power

ascending

descending

|

Operating frequency

ascending

descending

|

Cooling

ascending

descending

|

Power density

ascending

descending

|

Details | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MHS Induction generator

6 x 3 kW |

610 660 12 | MHS Induction generator | Integrated power measurement, short circuit detection, DC link monitoring, automatic frequency tuning, resonance frequency monitoring | - | System product | - | Data communication via CAN, electronic supply 24 VDC | - | - | - | IP 20, Device for mounting in a closed, metallic control cabinet | Prepared for installation on cabinet mounting plates | Book Size steel housing with stainless steel cover, (451 x 105 x 313) | 3 x 400 VAC +10% /-15%; 50/60 Hz; Network configuration TT or TN | In vertical installation position: 0°C ... 35°C | CE, NRTL Certification by TÜV SÜD for UL61010 | specific induction coils | 6 | 6 x up to 3 kW, total power 18 kW (depends on the operating frequency) | 2 ... 25 kHz, automatic operating point determination | Forced air cooling, power loss approx. 250W | 100 | to the product |

|

MHS Induction generator

4 x 3,5 kW |

610 640 01 | MHS Induction generator | Integrated power measurement, short circuit detection, DC link monitoring, automatic frequency tuning, resonance frequency monitoring | - | System product | - | Data communication via CAN, electronic supply 24 VDC | - | - | - | IP 20, Device for mounting in a closed, metallic control cabinet | Prepared for installation on cabinet mounting plates | Book Size steel housing with stainless steel cover, (451 x 105 x 313) | 3 x 400 VAC +10% /-15%; 50/60 Hz; Network configuration TT or TN | In vertical installation position: 0°C ... 35°C | CE, NRTL Certification by TÜV SÜD for UL61010 | specific induction coils | 4 | 4 x up to 3, 5 kW, total power 14 kW (depends on the operating frequency) | 2 ... 25 kHz, automatic operating point determination | Forced air cooling, power loss approx. 250W | 100 | to the product |

|

MHS Induction generator

4 x 4,5 kW |

610 640 30 | MHS Induction generator | Integrated power measurement, short circuit detection, DC link monitoring, automatic frequency tuning, resonance frequency monitoring | - | System product | - | Data communication via CAN, electronic supply 24 VDC | - | - | - | IP 20, Device for mounting in a closed, metallic control cabinet | Prepared for installation on cabinet mounting plates | Book Size steel housing with stainless steel cover, (451 x 105 x 313) | 3 x 400 VAC +10% /-15%; 50/60 Hz; Network configuration TT or TN | In vertical installation position: 0°C ... 35°C | CE, NRTL Certification by TÜV SÜD for UL61010 | specific induction coils | 4 | 4 x up to 4, 5 kW, total peak power 26 kW (depends on the operating frequency) | 2 ... 25 kHz, automatic operating point determination | Forced air cooling, power loss approx. 250W | - | to the product |

|

MHS Induction generator

4 x 6,5 kW |

610 640 00 | MHS Induction generator | Integrated power measurement, short circuit detection, DC link monitoring, automatic frequency tuning, resonance frequency monitoring | - | System product | - | Data communication via CAN, electronic supply 24 VDC | - | - | - | IP 20, Device for mounting in a closed, metallic control cabinet | Prepared for installation on cabinet mounting plates | Book Size steel housing with stainless steel cover, (451 x 105 x 313) | 3 x 400 VAC +10% /-15%; 50/60 Hz; Network configuration TT or TN | In vertical installation position: 0°C ... 35°C | CE, NRTL Certification by TÜV SÜD for UL61010 | specific induction coils (inductance 875 μH ± 150μH) | 4 | 4 x up to 6.5 kW, total peak power 26 kW (depends on the operating frequency | 2 ... 25 kHz, automatic operating point determination | Forced air cooling, power loss max. 350W | - | to the product |

|

MHS Induction generator

4 x 5 kW |

610 640 03 | MHS Induction generator | Integrated power measurement, short circuit detection, DC link monitoring, automatic frequency tuning, resonance frequency monitoring | - | System product | - | Data communication via CAN, electronic supply 24 VDC | - | - | - | IP 20, Device for mounting in a closed, metallic control cabinet | Prepared for installation on cabinet mounting plates | Book Size steel housing with stainless steel cover, (451 x 105 x 313) | 3 x 400 VAC +10% /-15%; 50/60 Hz; Network configuration TT or TN | In vertical installation position: 0°C ... 35°C | CE, NRTL Certification by TÜV SÜD for UL61010 | specific induction coils | 4 | 4 x up to 5 kW, total peak power 26 kW (depends on the operating frequency) | 2 ... 25 kHz, automatic operating point determination | Forced air cooling, power loss max. 250W | - | to the product |

|

MHS Controller PROFINET

|

610 610 02 | MHS Controller / fieldbus connection | Temperature control, system monitoring, fieldbus communication, bus coupler for up to 7 MHS power modules, power control, Software update via SD | PROFINET IO-Device | System product | 1 x Ethernet 10/100Mbit (on request) | Data communication via CAN, electronic supply 24 VDC | Heating system, PROFINET, CANopen, DC power supply | on request: 8 x DI: input delay: 3 ms / 8 x DO 24V, 0, 5 A, Short circuit protection | module made of steel with stainless steel cover for use in a closed, metallic control cabinet | IP 20 | Prepared for left-side mounting on the power module | 451 mm x 44 mm x 286 mm | 24 VDC / -10% +10% (21, 6 V – 26, 4) | In vertical installation position: 0°C ... 35°C | CE, UL, PROFINET | - | - | - | - | - | - | to the product |

|

MHS Controller CANopen

|

610 610 10 | MHS Controller / fieldbus connection | Temperature control, system monitoring, fieldbus communication, bus coupler for up to 7 MHS power modules, power control, Software update via SD | CANopen Node | System product | 1 x Ethernet 10/100Mbit (on request) | Data communication via CAN, electronic supply 24 VDC | Heating system, Fieldbus, CANopen, DC power supply | on request: 8 x DI: input delay: 3 ms / 8 x DO 24V, 0, 5 A, Short circuit protection | module made of steel with stainless steel cover for use in a closed, metallic control cabinet | IP 20 | Prepared for left-side mounting on the power module | 451 mm x 44 mm x 286 mm | 24 VDC / -10% +10% (21, 6 V – 26, 4) | In vertical installation position: 0°C ... 35°C | CE, UL | - | - | - | - | - | - | to the product |

|

MHS Controller EtherCAT

|

610 610 20 | MHS Controller / fieldbus connection | Temperature control, system monitoring, fieldbus communication, bus coupler for up to 7 MHS power modules, power control, Software update via SD | EtherCAT SubDevice | System product | 1 x Ethernet 10/100Mbit (on request) | Data communication via CAN, electronic supply 24 VDC | Heating system, EtherCAT, CANopen, DC power supply | on request: 8 x DI: input delay: 3 ms / 8 x DO 24V, 0, 5 A, Short circuit protection | module made of steel with stainless steel cover for use in a closed, metallic control cabinet | IP 20 | Prepared for left-side mounting on the power module | 451 mm x 44 mm x 286 mm | 24 VDC / -10% +10% (21, 6 V – 26, 4) | In vertical installation position: 0°C ... 35°C | CE, UL | - | - | - | - | - | - | to the product |