With the modular induction generators to the optimum system design

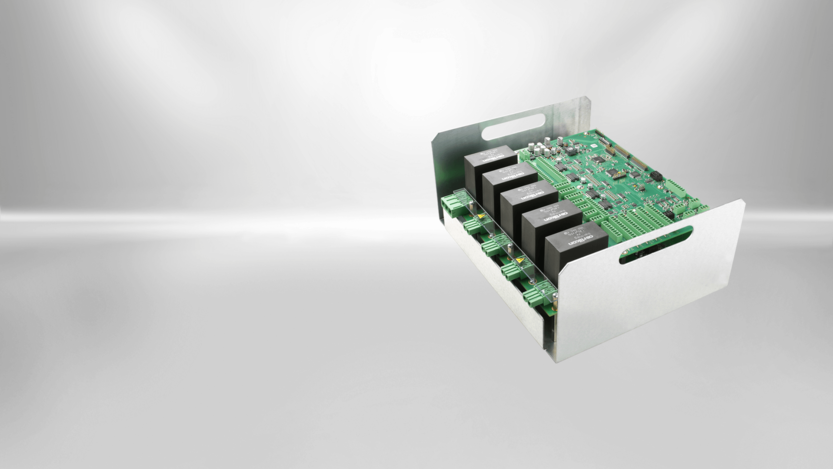

With the modular induction generators, Kendrion has developed a scalable system consisting of a controller and up to seven generator modules. These supply the inductors with optimally adapted power. The controller is integrated into the machine control system via a fieldbus such as PROFINET, ETHERCAT CANopen, or another fieldbus system.

The controller for the modular induction heating is a fieldbus-capable device for controlling up to seven power output stages that are directly connected via the module bus. In addition to system monitoring, the controller can also control or regulate the individual output channels. The actual temperature values are transmitted directly to the controller via a CAN fieldbus or made available by a higher-level controller. Extensive diagnostic options as well as integrated inputs and outputs, enable fast commissioning.

The modular induction generators are operated on the three-phase supply with a voltage of up to 400 V and a frequency of 50/60 Hz. The mains current is rectified and fed to the DC link, from which the inductors are individually supplied. They are activated by the controller of the modular heating system. The control range from 0% to 100% can be selected individually for each channel. By using the latest semiconductor switches, the output stages achieve high efficiencies at operating frequencies up to 25 kHz.

The modular induction generators are available in two configurations:

- The Induction Generator 4 x 7.5 kW module is designed to supply up to 4 induction coils (inductors) with an output of up to 7.5 kW each.

- The module Induction Generator 6 x 3 kW is designed for the supply of up to 6 induction coils (inductors) with an output of 3 kW each.

In addition to the modular induction generators, we can also provide customized solutions. Our customised induction heating are designed precisely to your heating requirements and additionally integrate different functionalities.

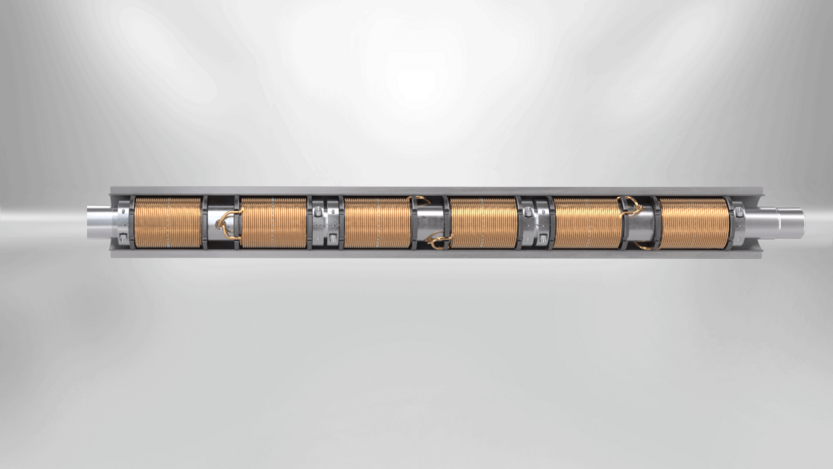

The inductors are tailor-made to fit your tools. These are often roller inductors that are permanently installed inside rollers, rolls, and cylinders. Alternatively, we speak of surface inductors, in which induction coils heat tools over a wide area. The heat is transferred without contact via a magnetic field.

General Technical Specifications

| Parameter | Value |

|---|---|

| Fieldbus compatible | Profinet, Ethercat, CANopen |

| Controller | Integrated controller for up to 42 channels |

| System performance | scalable up to 150kW |

| Mains voltage | 3x 400VAC |

| Size variation | Booksizeformat for switch cabinet mounting |

| Diagnostic functions | short-circuit detection, temperature monitoring, voltage monitoring, power monitoring, ... |

| Operating frequency | 2...25kHz |