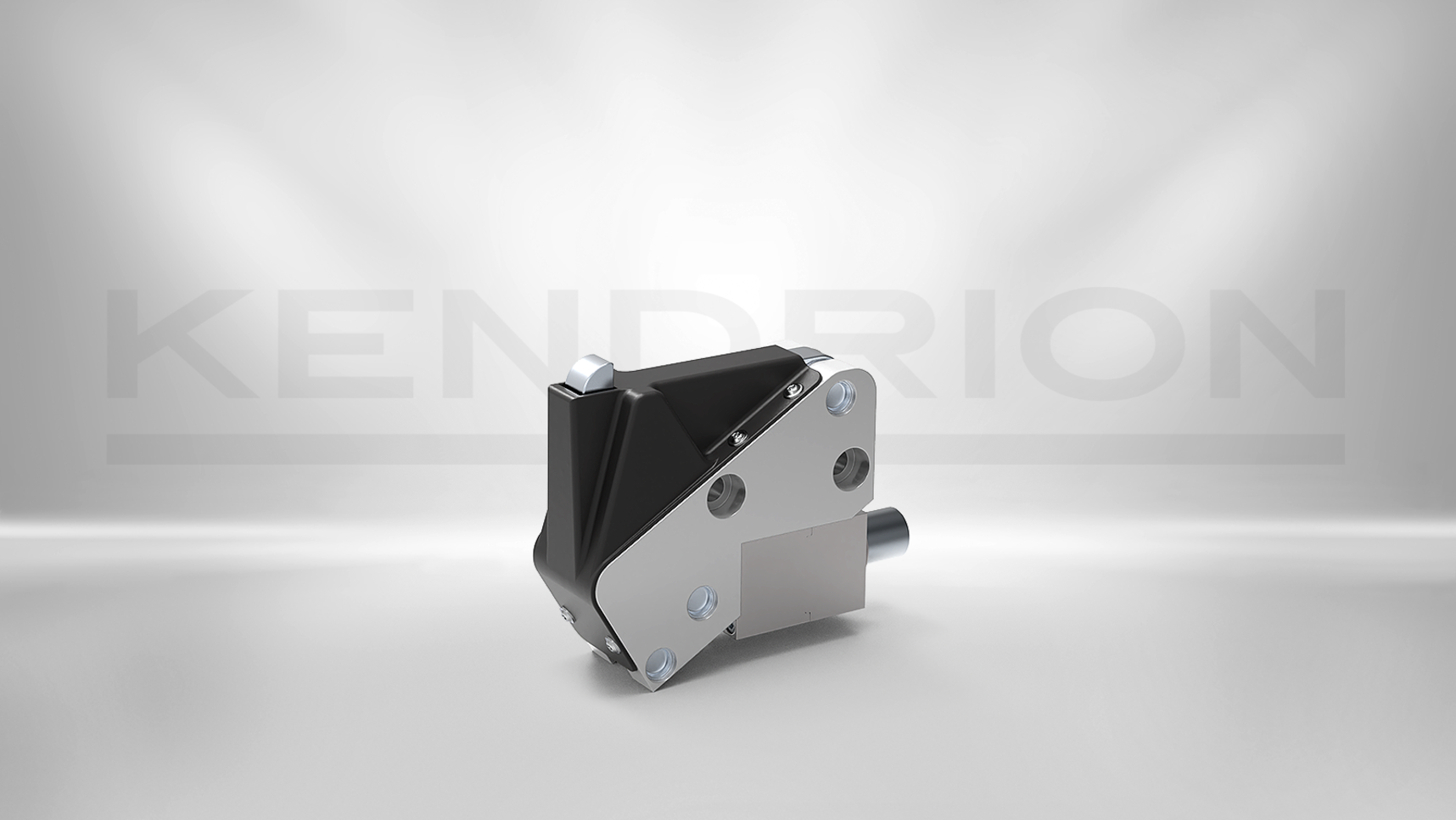

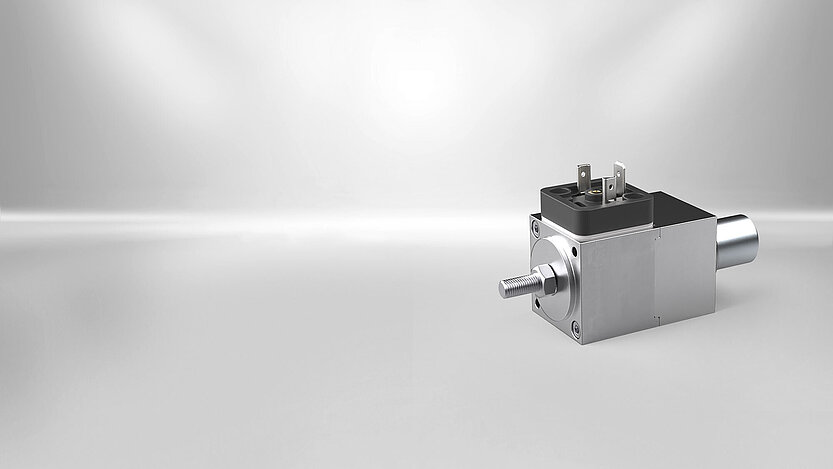

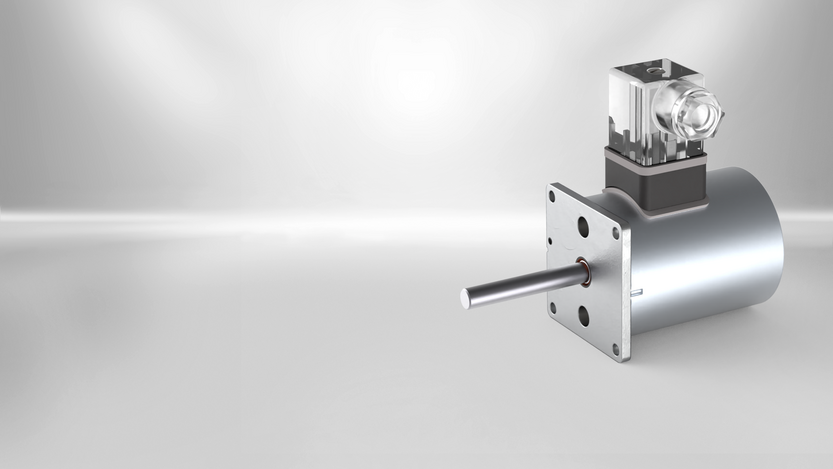

Electromagnetic stopper for quit and clean processes.

In pallet conveyor applications such as a pallet conveyor system or pallet transport system, pallet stoppers play a central role: they stop and position workpiece carriers precisely at processing stations or reliably separate pallets from the material flow, for example as singulators in conveyor technology.

As robust conveyor stopper, they ensure repeatable performance even in dynamic operations. Modern production environments demand high cycle rates, quiet and clean processes, and the lowest possible operating and maintenance costs.

For high loads and fast cycle times.

Kendrion's electromagnetic (electric) pallet stoppers are a powerful plug-and-play solution without pneumatics. As an electric stoppers (magnetic stoppers), they are actuated by our high performance linear solenoid and deliver proven performance for workpiece carriers weighing up to 25 kg at conveyor speeds of up to 20 m/min, validated in endurance testing. The 24 V DC control via standard PLC or IO modules reduces system complexity, enables quick commissioning, and eliminates the need for pneumatic peripherals.

Depending on the application, Kendrion stoppers can be equipped with an optional damping module. This ensures fast, precise, and at the same time gentle pallet positioning, even with high loads and dynamic processes in stopper conveyor setups.

Technical features

Maximum workpiece carrier weight: 25 kg (15 kg with damper)

Band speed: 20 m/min

Operating voltage: 24 V DC

On-time: 100%

Rated power: 40.3 W

IP protection class: IP40

Optional: Condition monitoring (e.g., end-of-travel detection)

Benefits at a glance

- Plug & play: 24 V DC control via standard PLC / I/O modules

- Compact and extremely space-saving design

- No compressed-air infrastructure required, enabling lower energy and operating costs

- Very short switching times for high cycle rates

- Available with an optional damping module for fast, accurate, and gentle positioning

- Proven performance for loads up to 25 kg at conveyor speeds up to 20 m/min

Electric pallet stoppers operate without compressed air and therefore do not require any pneumatic components. This eliminates the entire compressed air/ penumatic infrastructure, including generation, distribution and maintenance.

As a result, system complexity is reduced, energy and operating costs are lowered, and typical pneumatic issues such as air leaks, exhaust noise or inconsistent switching times are avoided.

In addition, electric operation is significantly quieter and allows for more precise and repeatable control of the stopping position and motion.

Another key advantage is the easy integration of monitoring and diagnostic functions, such as end-position detection, condition monitoring or feedback signals to the control system. This improves process reliability, transparency and maintenance planning.

Electric pallet stoppers are particularly suitable for systems with high demands on energy efficiency, noise reduction and low maintenance, as well as for applications where a compressed air supply is not available or not desired.

The oil-free, compressed-air-free operation without exhaust air emissions also allows use in hygiene-sensitive and clean production environments, such as electronics manufacturing or areas with increased cleanliness requirements.

In addition, electric pallet stoppers are well suited for automated conveyor systems with high cycle rates, precise positioning requirements or an increased need for process monitoring and diagnostic functions. The easy integration of feedback signals supports high process reliability and transparency.

An electric pallet stop achieves very short switching times and is therefore particularly suitable for applications with high cycle-rates, for example as a separator in transfer and pallet conveyor systems. The exact response time depends on the respective stopper type (stroke, damping, load) and the control system.

The load capacity of an electric pallet stopper is defined by the accumulation load acting on the stopper.

The decisive factors here are the mass and number of accumulating workpiece carriers, as well as the friction conditions between the workpiece carrier and the conveyor belt and belt speed.

Based on these parameters, the pallet stopper is designed to ensure safe and reproducible stopping of the workpiece carriers under the respective operating conditions.