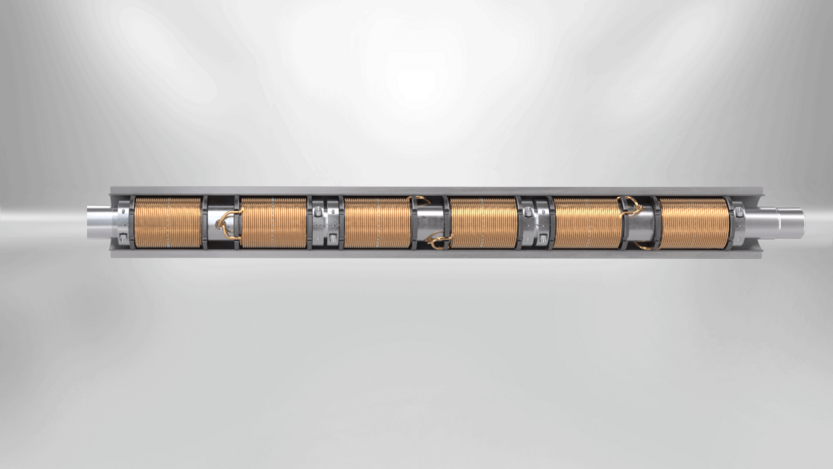

Induction heating improves your industrial processes

In industrial processes such as the production of synthetic fibers or in the area of packaging machines, precisely and dynamically controllable heat with a homogeneous distribution is essential. The generation of the required heat through an innovative, inductive heating concept offers many advantages. An inductive heating system tailored to your application requirements makes the advantages of inductive heating available to you. Compact heating systems include 3 main functions:

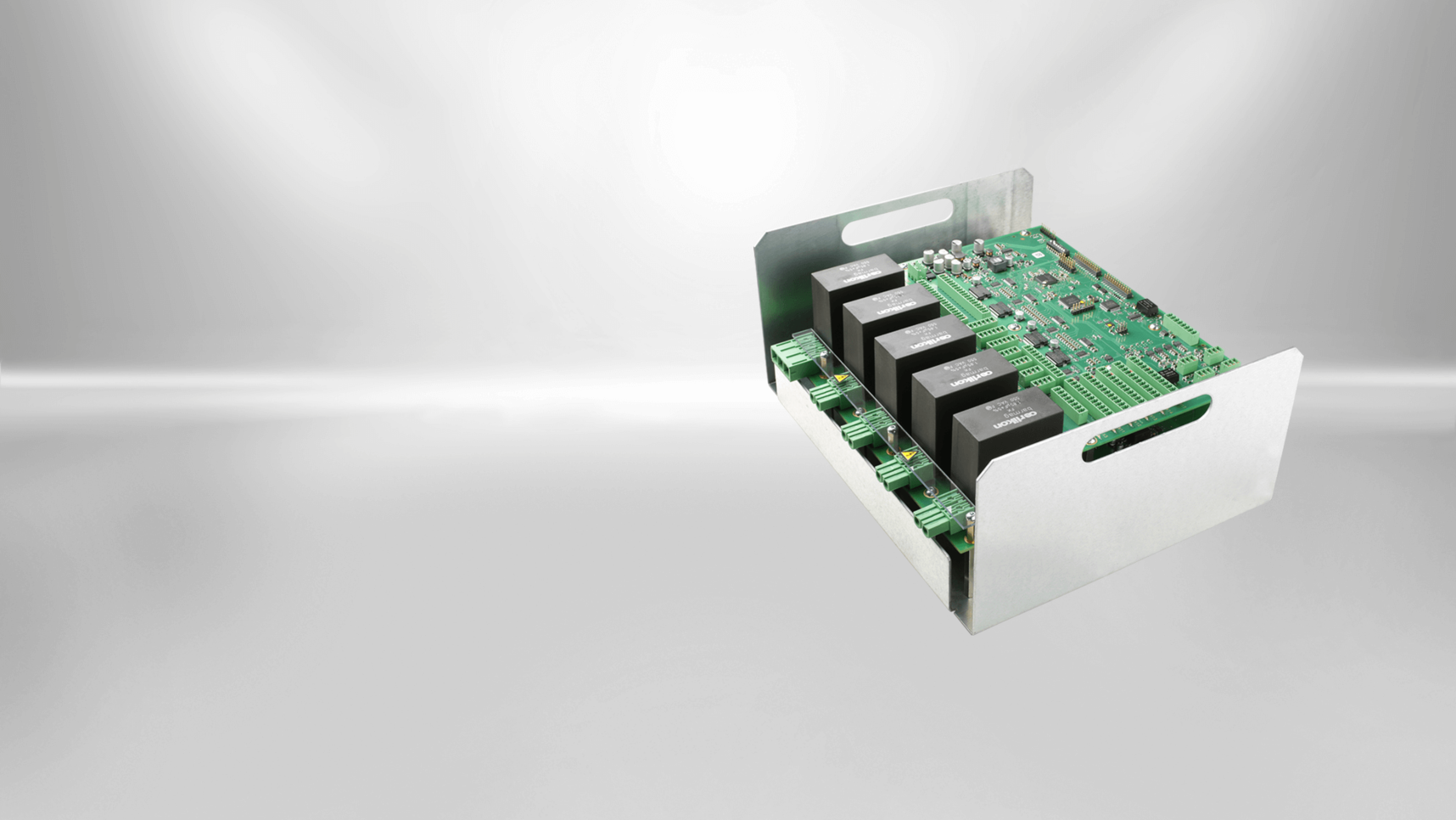

Power section

By using state-of-the-art semiconductor switches, our power amplifiers achieve high efficiencies at operating frequencies of up to 50kHz. The power class is in the range up to 50kW, with up to 10kW per channel and up to 8 independent channels. The output stages are short-circuit-proof and designed for continuous operation.

Control and Communication

The control is realised with microcontrollers on which the temperature control, the system monitoring, the adaptation of the inductors to the output stages and the communication, e.g. via a fieldbus such as EtherCAT with a master control are implemented.

Temperature measurement

To detect the temperature of the heated workpieces, we utilise common industrial sensor types such as PT1000/100 or thermocouples. The temperature measurement can be implemented on the power electronics or as a separate unit.