High-Level Product Design through Model-Driven Development

In today's ever-evolving technological landscape, the increasing complexity of modern systems necessitates continuous improvements in development processes to uphold the highest quality standards. Model-Driven Development (MDD) emerges as a pivotal approach capable of profoundly enhancing various facets of traditional product design processes. MDD not only mitigates project risks and reduces costs but also promotes seamless collaboration among engineers spanning diverse disciplines.

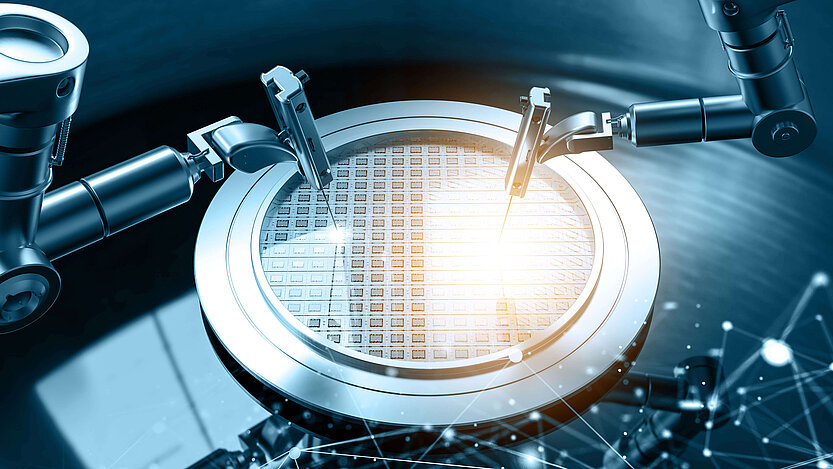

Our journey began decades ago with the implementation of modeling and simulation techniques, such as SPICE, to analyze electronic designs and utilize FEM analysis for board design optimization. Since 2012, we have pushed boundaries further by generating code for processors and FPGAs from system models. You can explore our success story with the Brakebox Wafer Handler on the MathWorks website.

At 3T, we optimize component placement and are able to create high-power-density designs because of our power analysis. We have already developed simulation models for our VIPER and PEPPER platforms. This allows us to quickly assess our customer's specific mechatronic challenges and adapt our simulation models to generate controller software tailored to the customer's needs.

With our commitment to Model-Driven Development, we stay at the forefront of innovation to meet the evolving demands of today's complex product design landscape.

Drawing on our extensive experience, we have refined and optimized the development process, resulting in reduced project risks and the delivery of high quality products.

Our expertise is most prominent in the field of motion control, where modeling plays a pivotal role. By comprehending mechatronic systems through model-driven development, we gain deeper insights into the challenges, expediting the development of effective solutions.

Bert van den Berg, 3T Business Unit Manager