Certified explosion protection

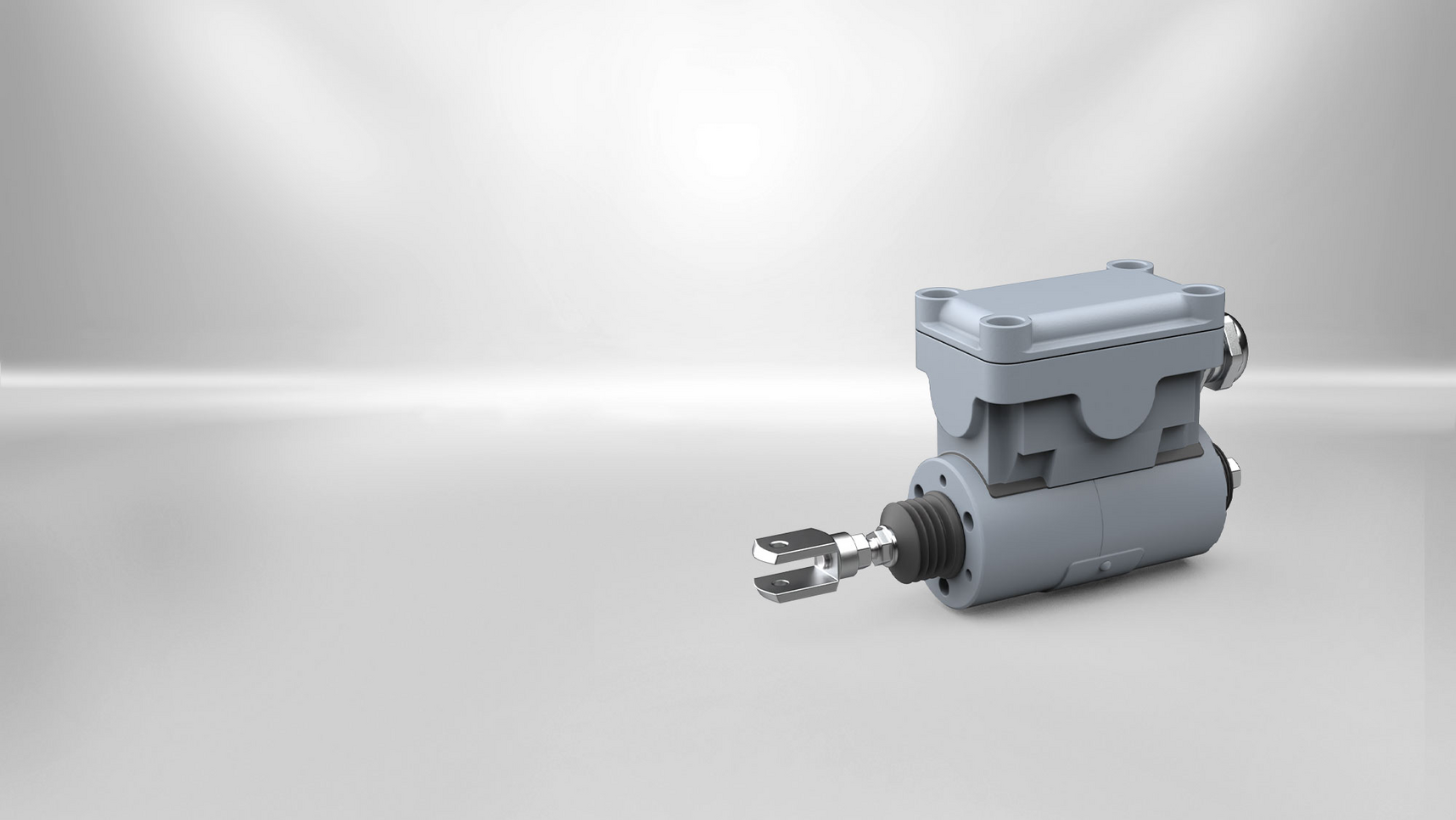

Kendrion is a manufacturer of ATEX linear solenoids, which are primarily used where sparking constitutes a significant safety hazard. These explosive areas with flammable gases and vapors are found in mining, in refineries, on oil platforms, or in other chemical plants.

The explosion-proof linear solenoids of Kendrion comply with the European ATEX guideline 2014/34/EU for devices and protection systems intended for proper use in explosive areas.

This was tested by the Physical-Technical Federal Institute (Physikalisch-Technische Bundesanstalt, PTB) resp. by the IBExU (Institute for Safety Technology) according to EN 60079.

Ex-Solenoids with Ignition Protection Type „Increased Safety”, Ex “e”

The most critical requirement for explosion-proof solenoids is to prevent the ignition of an explosive atmosphere in the operational environment. This means that the solenoid may neither reach temperatures above the temperature class of potentially occurring gases nor form electrically or mechanically induced sparks.

All linear solenoids which Kendrion offers for explosion protection are compliant with the ignition protection type “Increased Safety”, Ex “e”. For this purpose, special design precautions have been taken to shield the coil inside the solenoid from its environment. Furthermore, the components of the solenoid were designed to achieve an extremely high temperature resistance. Thus, the Ex-solenoids can be used in the temperature class T4 (up to + 135°C).

Linear Solenoids by Kendrion for Explosion Protection

Kendrion offers a broad portfolio of standard linear solenoids in Ex-design. The electromagnetic actuators convince through:

✓ high forces

✓ dynamic switching

✓ long service life

The ATEX linear solenoid consists of a pot magnet and a connector housing, providing a connection for the protective conductor, according to EN 60079.

Both the steel housing and the aluminum connector housing are designed in the ignition protection type “e”. The models from size 10 on also have a mounting base. The Ex-solenoids are suitable for use at an ambient temperature of -20°C to +40°C (with type 41 03E13K03 from -20°C to +35°C). Depending on the rated current, the solenoid must be operated with a suitable upstream fuse resp. with a motor protection switch provided by the customer. Furthermore, a varistor must ensure that the breaking voltage is not exceeded.

Product finder ATEX linear solenoids

Technical Data of Explosion-Proof Solenoids

Explosion protection: II 2G Ex eb IIC T4 Gb, Duty Cycle 100%, Protection class of device and connection IP54

| Type | Height x Length | Supply voltage | Nominal Power | Stroke | Force |

|---|---|---|---|---|---|

|

4101E06K00 Size 06 | 123 x 230 mm | 24V DC | 21W | 15mm | 20N |

|

4101E07K00 Size 07 | 133 x 240 mm | 24V DC | 25W | 20mm | 30N |

|

4101E09K00 Size 09 | 150 x 260 mm | 24V DC | 32W | 20mm | 50N |

|

4103E10K00 Size 10 | 150 x 285 mm |

24 V DC 110V DC |

50W 47W | 25mm | 60N |

|

4103E11K00 Size 11 | 116 x 315 mm | 24V DC | 40W | 30mm | 75N |

|

4103E11K03 Size 11 | 115 x 215 mm | 200V DC | 48W | 15mm | 160N |

|

4103E13K00 Size 13 | 180 x 315 mm |

24V DC 110V DC 180V DC 205V DC |

56W 60W 63W 62W | 30mm | 120N |

|

4103E13K03 Size 13 | 180 x 315 mm | 200V DC | 59W | 15mm | 240N |

|

4103E14K00 Size 14 | 180 x 410 mm | 24V DC | 77W | 40mm | 150N |

|

4103E16K00 Size 16 | 210 x 475 mm | 24V DC | 83W | 50mm | 160N |

|

4103E18K00 Size 18 | 205 x 490 mm | 24V DC | 106W | 50mm | 250N |