Customized miniature valves

Diaphragm isolating valves and bistable valves

The miniature valves of Kendrion are small valves which were developed in cooperation with our customers. They range from diaphragm isolating valves for the beverage industry and medical engineering to bistable miniature valves for the end consumer market.

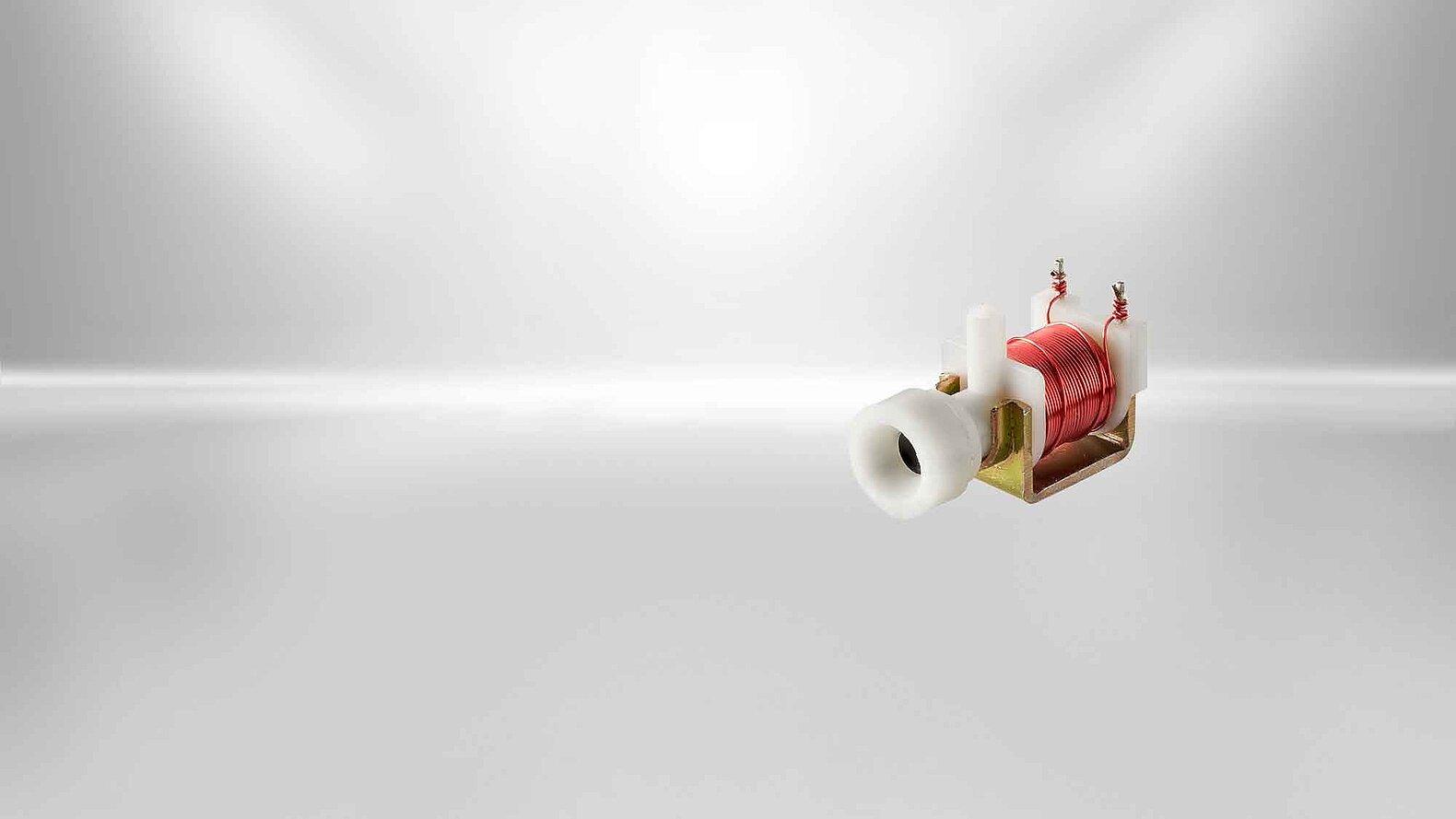

Diaphragm isolating valves are particularly suitable for applications controlling aggressive or sensitive media. The advantage is that the medium does not get in touch with metallic components, preventing the medium from being contaminated. The material of the diaphragm is determined by the medium.

Bistable valves hold currentless in the closed and opened position of a 2/2 directional valve. The main advantage of the battery-operated valves is that they can rest in closed and open position for a longer period of time. A short pulse closes or opens the valve, significantly extending the battery lifetime

All miniature valves excel by the fact that they have been tailor-made. This allows the customer to determine the position and shape of the electric and mechanical connections, facilitating installation and making perfect use of installation space. Furthermore, only the required functions are realized so that - compared to standard valves - significant cost reductions can be achieved.

The miniature valves of Kendrion are designed for large quantities. The development costs are born by Kendrion whereas the customer pays for the tools and, if necessary, auxiliary devices. This allows Kendrion to offer miniature valves at lowest costs.

Please note that the magnet valves described are all product examples which are not available over the counter.

Technical data

| Parameter | Value |

|---|---|

| Valve type | 2/2 directional and 2/3 directional valves in NC- and NO-design |

| Supply voltage | 1.5 V DC - 24 V DC |

| Operating pressure | 4 - 10 bar |

| Medium | liquid / gaseous / aggressive |

| Switching time | 3 - 50 ms |

| Service life | > 1 million switchings |

| Comment | All miniature valves of Kendrion are customer-specific developments. |

Custom designed Miniature Two-Way Valve

The Miniature Two Valve (MTV) was designed to be mounted directly onto a printed circuit board (PCB). The configuration shown was designed to mate directly onto an aerosol can. Roughly the size of a thumb tack, the MTV is one of the smallest valves in the Kendrion line up. It was designed to be used in conjunction with a Pulse Width Modulated (PWM) electrical circuit to keep the power draw to a minimum. It is capable of 120,000 cycles using 2 AA batteries.

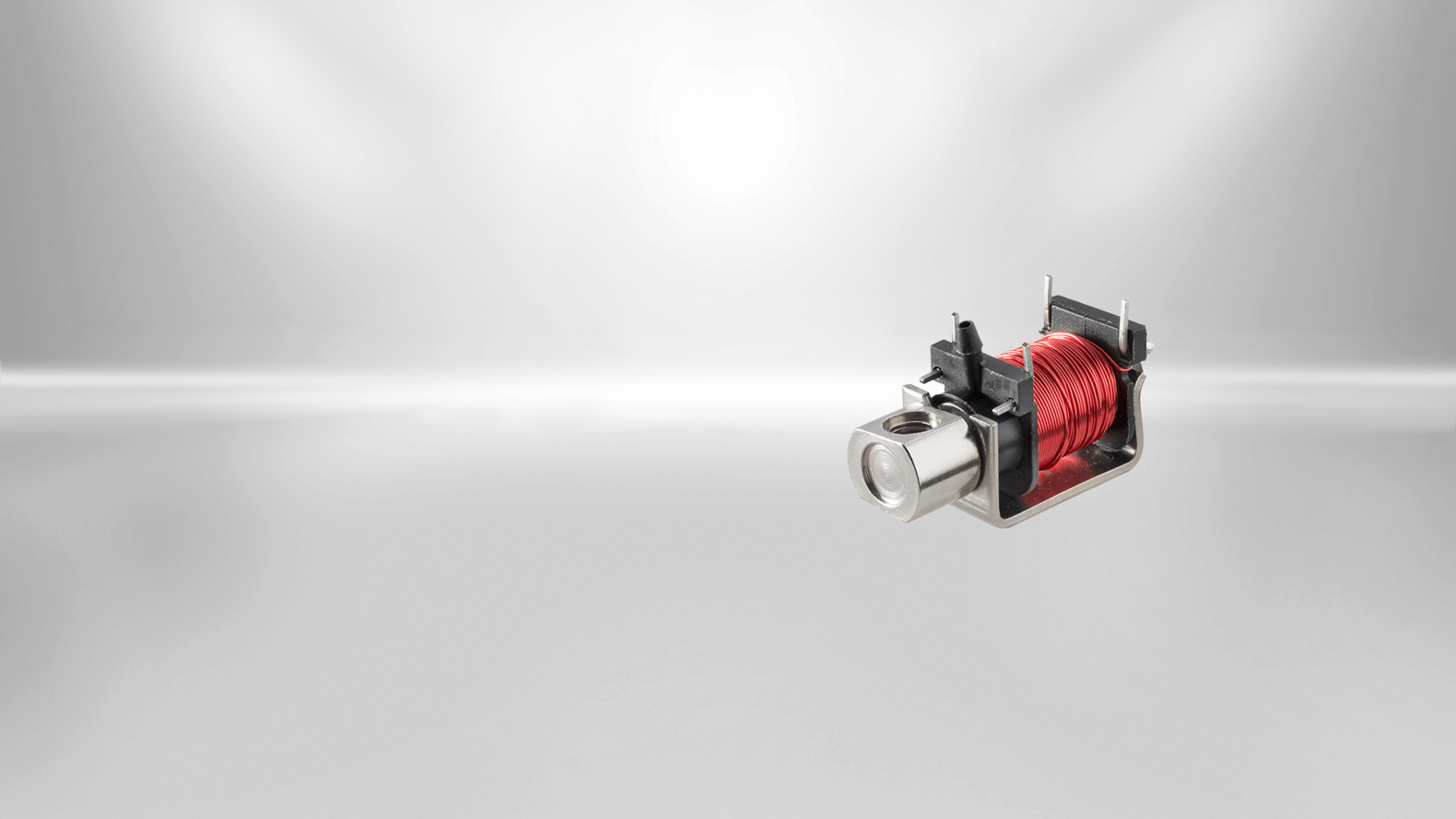

Custom designed Small Pneumatic Valve

The Small Pnuematic Valve (SPV) was designed to work with compressed gas. It was optimized to work with a 9V battery and Pulse Width Modulation (PWM). The PWM signal allowed the valve size to be reduced and in turn reduced the cost of the valve. The Small Pnuematic Valve can be direclty mounted to a Printed Circuit Board (PCB).

Custom designed Vacuum Isolation Valve

Custom designed Vacuum Isolation Valve The Vacuum Isolation Valve (VIV) was designed with dosage control and fluid isolation in mind. A diaphragm with a special support washer was used for this vacuum application to isolate the metal components from the controlled fluid. The Vacuum Isolation Valve was designed to snap into place without the need for additional fasteners. The Valve was designed for use with Pulse Width Modulation (PWM) to keep the overall size of the system to a minimum. The PWM also allowed for improved battery operation. 100,000 cycles on 2 AA batteries typical.

Custom designed Bistable Isolation Valve

The Miniature Bi-Stable Isolation Valve (BIV) was designed with size and battery life in mind. Powered Metal was used to reduce the footprint of the valve while allowing for integrated mounting features. A diaphragm was used to isolate the fluid from contact with metal. A permanent magnet is used to latch the valve in the open or closed position to reduce the draw on the battery while dispensing. Pins were also integrated into the design to detect when fluid was no longer present and signal the end user when it was time to re-fill the supply fluid. All of this in a package roughly the size of a thumb tack.

Custom designed 3 Way Pneumatic Valve

The 3 Way Pneumatic Valve (3PV) was designed with battery performance and speed in mind. The 3PV uses stamped components to keep size and cost down while reducing the moving mass of the armature. The result is cycle times in 1 millisecond range. The Valve was designed for use with a 9V battery and Pulse Width Modulation (PWM) to improve battery life. The plastic injection molded valve components integrated a previously seperate component that simplified the assembly process and reduced the system cost. The Valve is Printed Circuit Board (PCB) mountable. The valve was tested beyond 20,000,000 cycles.