Rotary Solenoids from Kendrion

Precise positioning and maximum durability

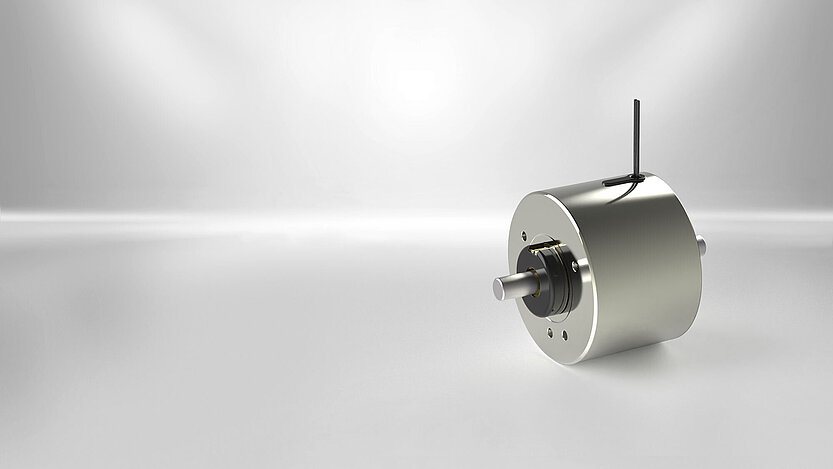

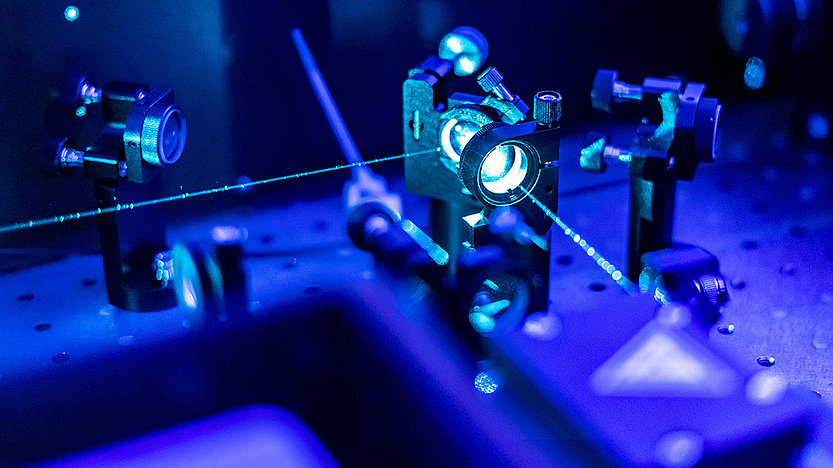

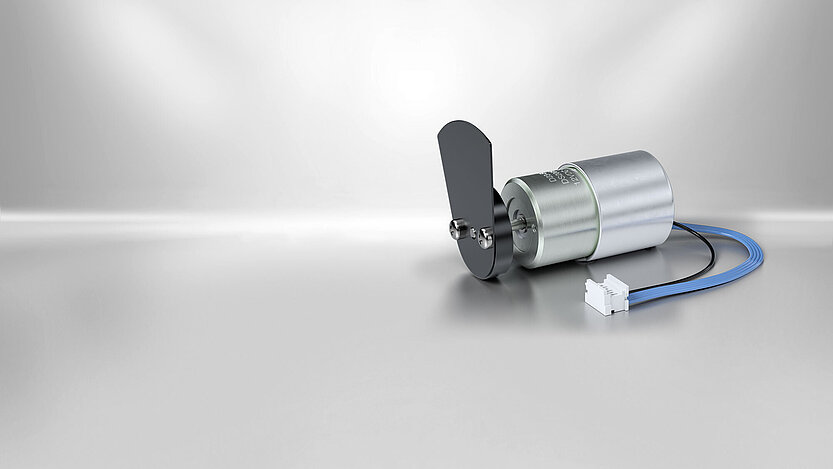

The Rotary Solenoids from KENDRION especially match applications in mechanical engineering, medical and laboratory technology, or the field of mobile machinery & transportation. They have a proven record as activation solenoids for sorting gates, throttles, and locking systems. A shaft with ball bearings on both sides ensures precise positioning and maximum durability. Because it is insensitive to linear acceleration, such rotary solenoids are also used for railway engineering as well as devices in aircraft.

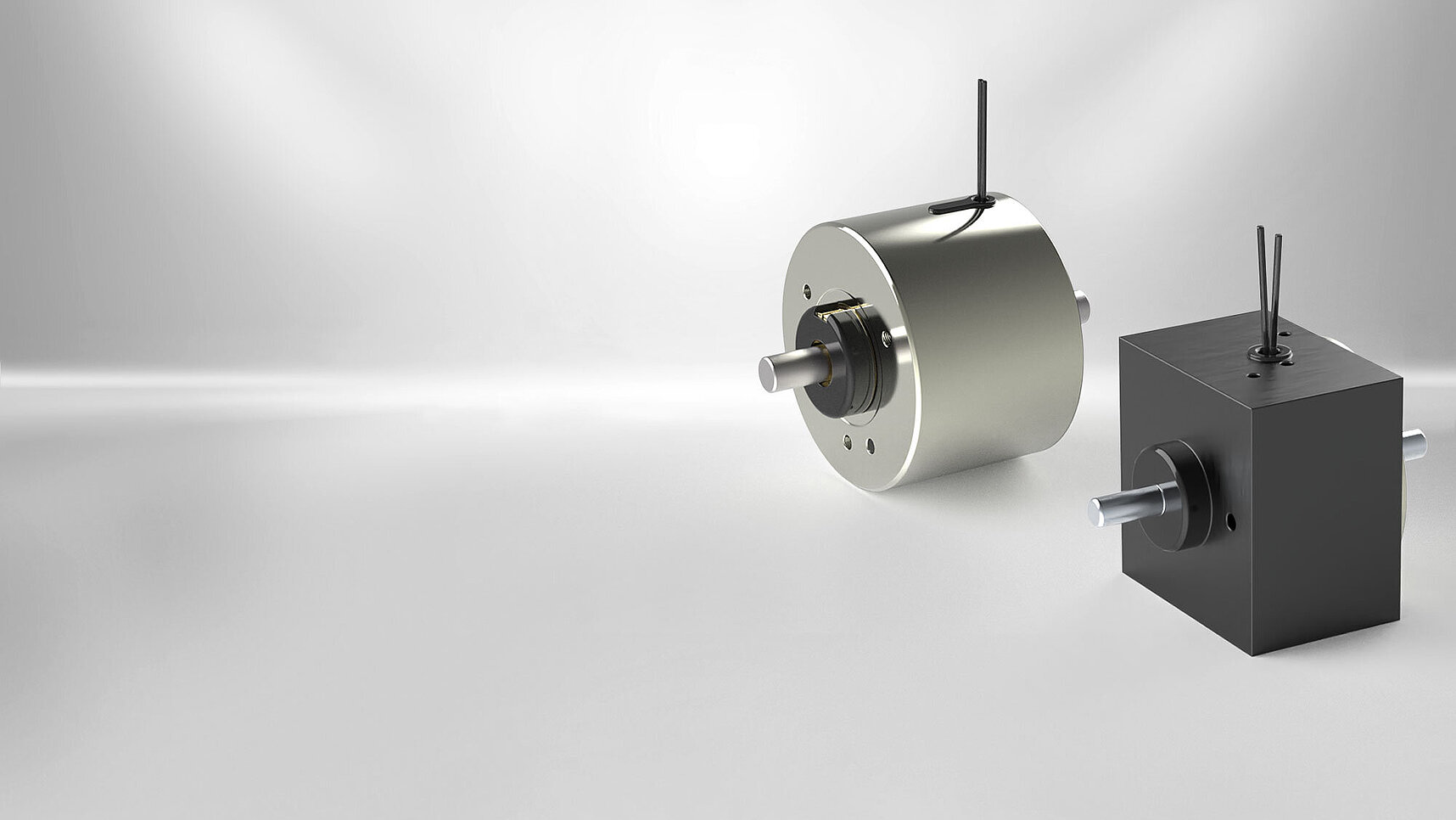

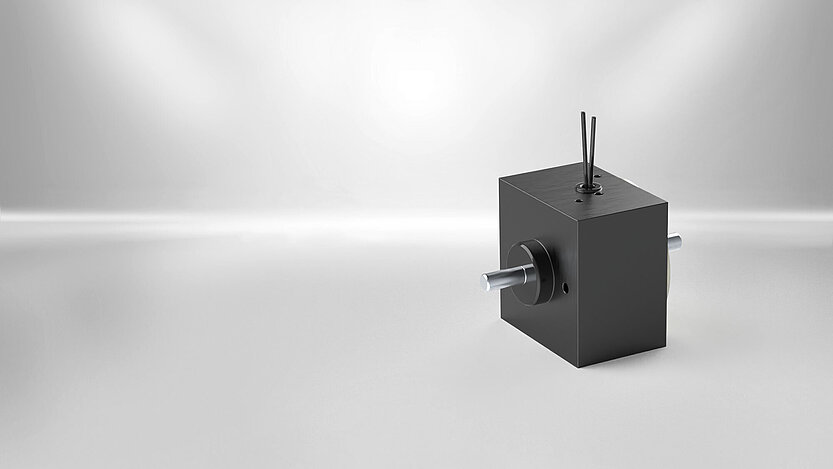

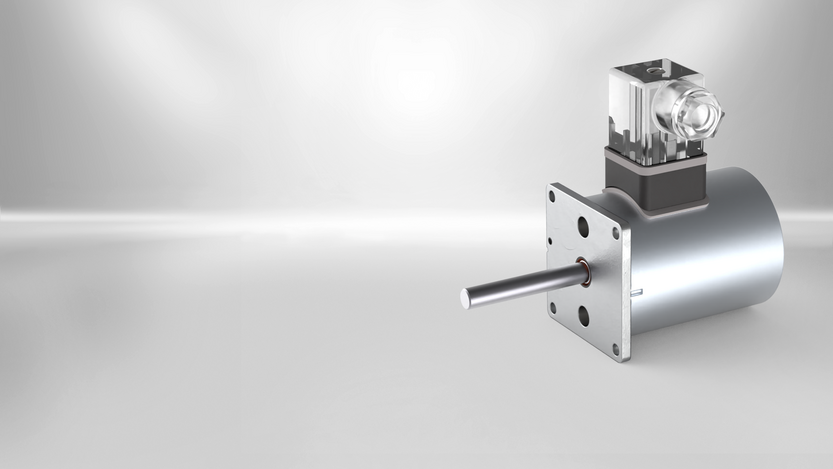

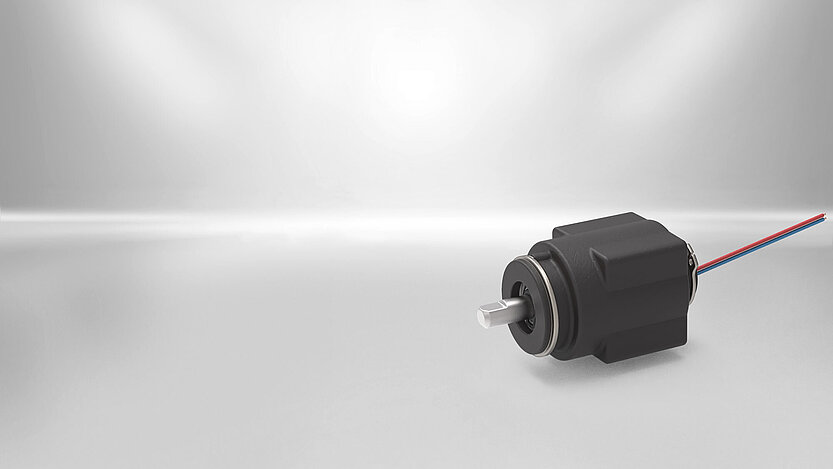

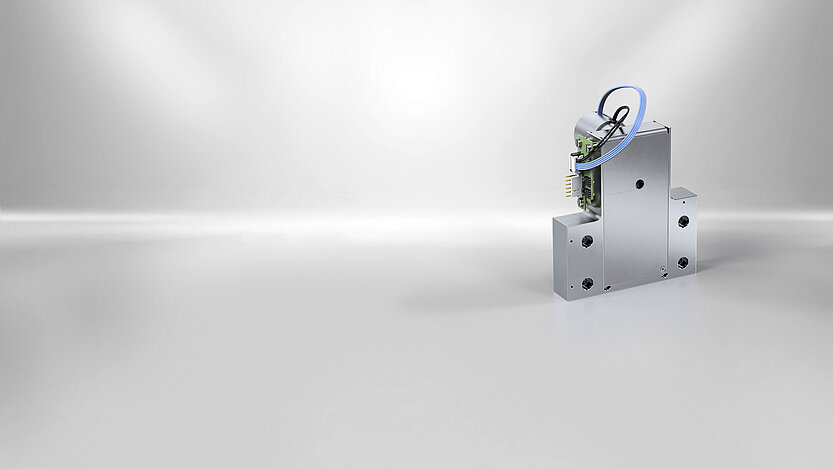

Single-stroke versions are available in two versions. The D series consists of rotary solenoids in a cylindrical form factor. The E series features a square form factor, offering higher efficiency with more torque at a minimum of space.

The rotary solenoids are available in a variety of models. Basic designs are single-stroke rotary solenoids with return spring and reversing rotary solenoids with two coils. Custom designed versions for special applications are available on request. These include models with plug-in terminals, modified shaft, or application-specific mounting holes.

Standard version and customization

Preferred models are designed for 24 V DC operation and 100% ED. All models are available for pivotal movements between 25° and 95°. The model BOR with shafts on both sides can be used as a right-handed or left-handed version with rotary angles between 45° or 95°. These solenoids are equipped with a return spring mounted at the right-hand shaft. Depending on the size of the solenoid, its rotary angle, and the duty cycle, it might be necessary to use a so-called „soft“ return spring. The order number of these rotary solenoids consists of the additional code „DS9429“ for easy recognition.

Alternative shaft designs, as well as models with mounting flange or reverse rotary solenoids, are available on request. Possible modifications also include individual solenoid designs for special operating voltages or specific duty cycles, as well as individual connection technologies, such as custom-made cable strands or terminals. Generally, these solenoids are designed for DC operation at a nominal operating voltage of 24 V. Using an additional external rectifier, models designed for 205 V DC operation can be operated directly at the mains power supply.

General Technical Specifications

| Parameter | Value |

|---|---|

| Nominal voltage | 24 V DC / 205 V DC, other voltages on request |

| Duty cycle | 100% ED / 40 / 25 / 5% ED on request |

| Connection | Flying leads, standard length 20 cm / other dimensions on request |

| Rotary angle | 25° / 35° / 45° / 65° / 95° |

| Inital torque Type D | 0.045 Ncm - 200 Ncm |

| Inital torque Type E | 0.2 Ncm - 480 Ncm |

| Thermal classification | B |