Our Vario Line

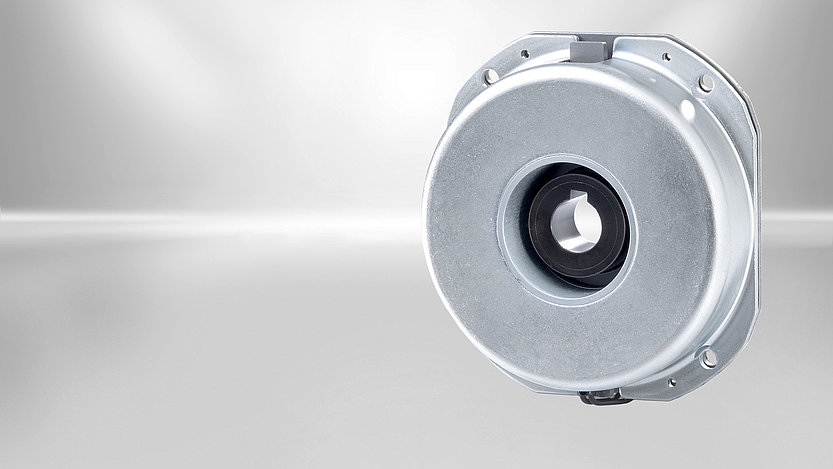

The Vario Line includes DC spring-pressure single-disc brakes, which can be matched to the individual application due to a wide range of variants.

Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off. By means of the electromagnetic force or an additionally mounted hand lifting device, the braking effect can be neutralized. Fitting dimensions and the grading of the type series of the VARIO LINE are matched to IEC motors.

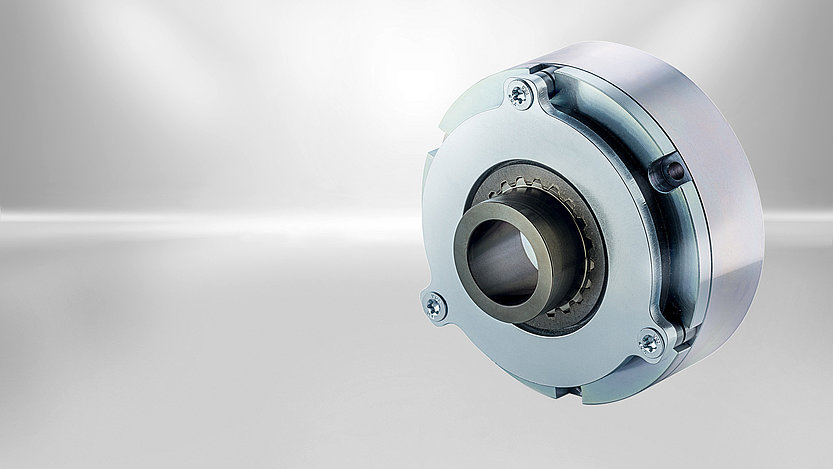

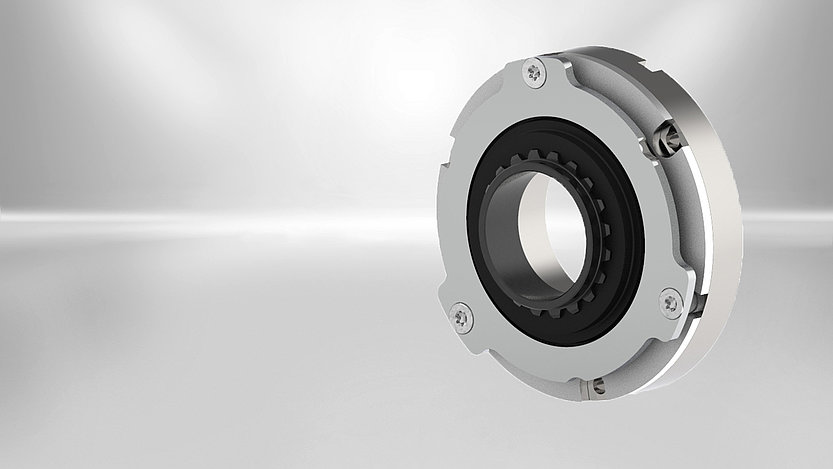

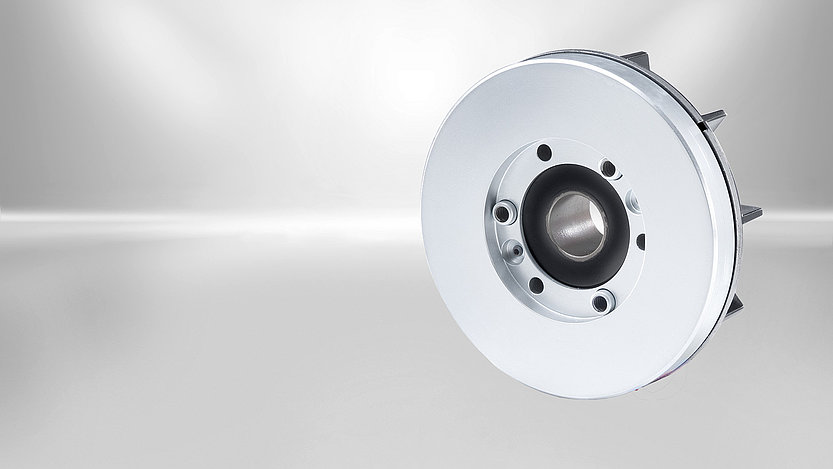

Operating principle

The spring-applied single-disc brake is designed to operate dry. The force generated by an electromagnetic field is utilised to overcome the braking effect produced by the spring force. The spring-applied single-disc brake engages in unpowered condition and releases when DC voltage is applied. The form-fit connection between the friction disc and hub and the connection of the hub with the machine shaft (e.g. motor shaft) ensure that the torque generated by the spring-applied single-disc brake (brake torque) is reliably transmitted to the machine (motor).

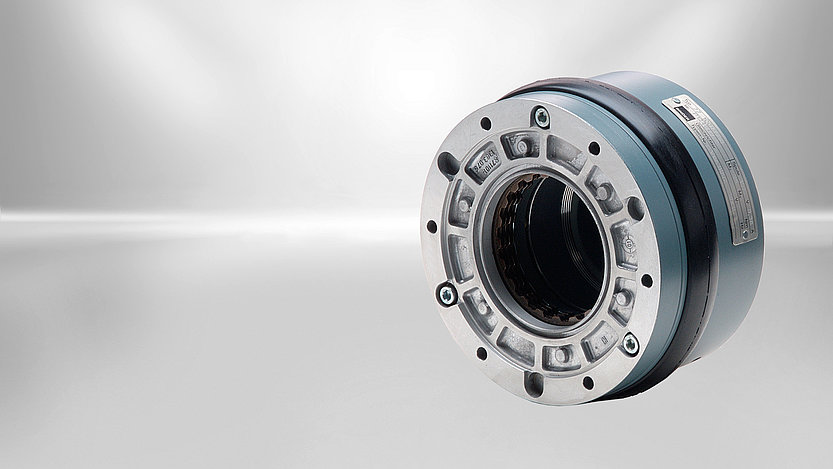

Brake design

The solenoid housing of the spring-applied single-disc brake accommodates the firmly fitted field coil featuring silicone-free connecting cables on the brake circumference. The solenoid housing also comprises the compression springs which press the friction disc over the armature against the friction plate or flange and thus against the fixing surface to generate the braking effect of the spring-applied brake. Spacer sleeves are provided to adjust the air gap 's'. The friction disc has a spline toothing or square socket and can be moved on the hub in axial direction. When DC voltage is applied to the field coil of the spring-applied single-disc brake, the spring force is overcome by the electromagnetic field force. This causes the armature to be released and the braking effect to be neutralised. The shaft to be braked is not subjected to any axial force by the brake. When using brakes with hand release, openings must be provided in the part enclosing the brake (e.g. fan cover) so that the hand release lever can be installed. The hand release allows the brake to be released manually (e.g. in case of power failure). When a collar is fitted to the brake, the hand release can only be operated by pushing the lever away from the fixing surface.